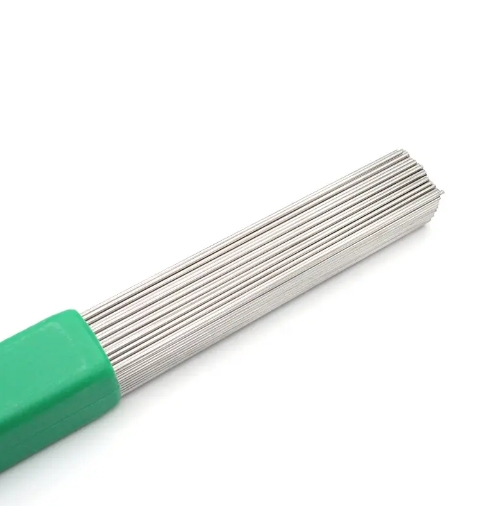

When welding aluminum, wire and electrode selection play a vital role in determining the quality and durability of the weld. ER1100 A5.10 Aluminum Welding Wire MiG Rods and Rods are one of the most popular choices in the welding industry. This particular product is highly sought after for its superior functionality and performance in a variety of welding applications.

ER1100 is a high-strength alloy with excellent chemical and weather resistance. This makes it ideal for applications where welding materials are exposed to harsh environmental conditions or corrosive substances. Additionally, ER1100 is known for its relatively soft characteristics, making it highly formable and suitable for use in thin gauge and foil products. This unique combination of properties makes ER1100 a versatile and widely used alloy in the welding industry.

One of the main advantages of using ER1100 A5.10 aluminum welding wire, rods and rods is its excellent formability. This allows welders to easily work with the material, especially in applications requiring complex shapes and designs. The alloy’s softness also makes it easy to work, making it a first choice for welding thin gauge aluminum plates and foils. Additionally, the formability of ER1100 ensures welded joints are strong and durable, providing long-lasting performance.

In addition to its formability, ER1100 offers excellent weldability, making it a popular choice for both novice and experienced welders. The alloy’s compatibility with MIG welding processes further enhances its usability, resulting in efficient, high-quality welds. Whether it’s automotive parts, aerospace structures or architectural elements, ER1100 A5.10 Aluminum Welding Wire MIG electrodes and rods provide reliable and consistent welds that meet the stringent requirements of every industry.

ER1100 also has excellent thermal conductivity, a critical factor in welding applications. The alloy’s ability to efficiently dissipate heat helps minimize the risk of deformation and warping during welding. This is especially important when working with thin aluminum materials, as it ensures that the welded part maintains its dimensional stability and structural integrity. The combination of excellent thermal conductivity and formability makes ER1100 ideal for welding applications requiring precision and accuracy.

The ER1100 A5.10 aluminum welding wire MiG electrodes and rods stand out as reliable and versatile solutions for aluminum welding. ER1100 offers excellent chemical and weather resistance, as well as formability, weldability and thermal conductivity, providing a full range of advantages to welders in a variety of industries. Whether for complex manufacturing or structural assembly, the ER1100 has proven to be a valuable ally in achieving high-quality and durable welding of aluminum materials.

Post time: Aug-21-2024