AWS A5.7 ERCuSn-C Copper Alloy Welding Wire is designed for joining copper and copper-tin alloys. Excellent flow and crack resistance ensures long-lasting welds, making it an ideal choice for automotive, marine and industrial applications.

AWS A5.7 ERCuSn-C Copper Alloy Welding Wire excels in welding copper-based materials where high strength and corrosion resistance are required. AWS A5.7 ERCuSn-C Copper Alloy Welding Wire meets stringent industry standards with precise tin and phosphorus content to produce a smooth, stable arc with minimal spatter. Compatible with both gas tungsten arc welding (GTAW) and gas metal arc welding (GMAW) processes, it is a versatile choice for both manual and automated operations. Industries such as shipbuilding, HVAC, and electrical manufacturing benefit from reliable, leak-proof joints and adaptability to complex welding scenarios.

AWS A5.7 ERCuSn-C Copper Alloy Welding Wire maintains mechanical integrity under stress. The phosphor bronze composition ensures that the weld resists fatigue and deformation even in high vibration environments such as ship engines or heavy machinery. AWS A5.7 ERCuSn-C Copper Alloy Welding Wire minimizes post-weld porosity, reduces the need for expensive rework, and is suitable for repairing bronze castings or joining dissimilar metals.

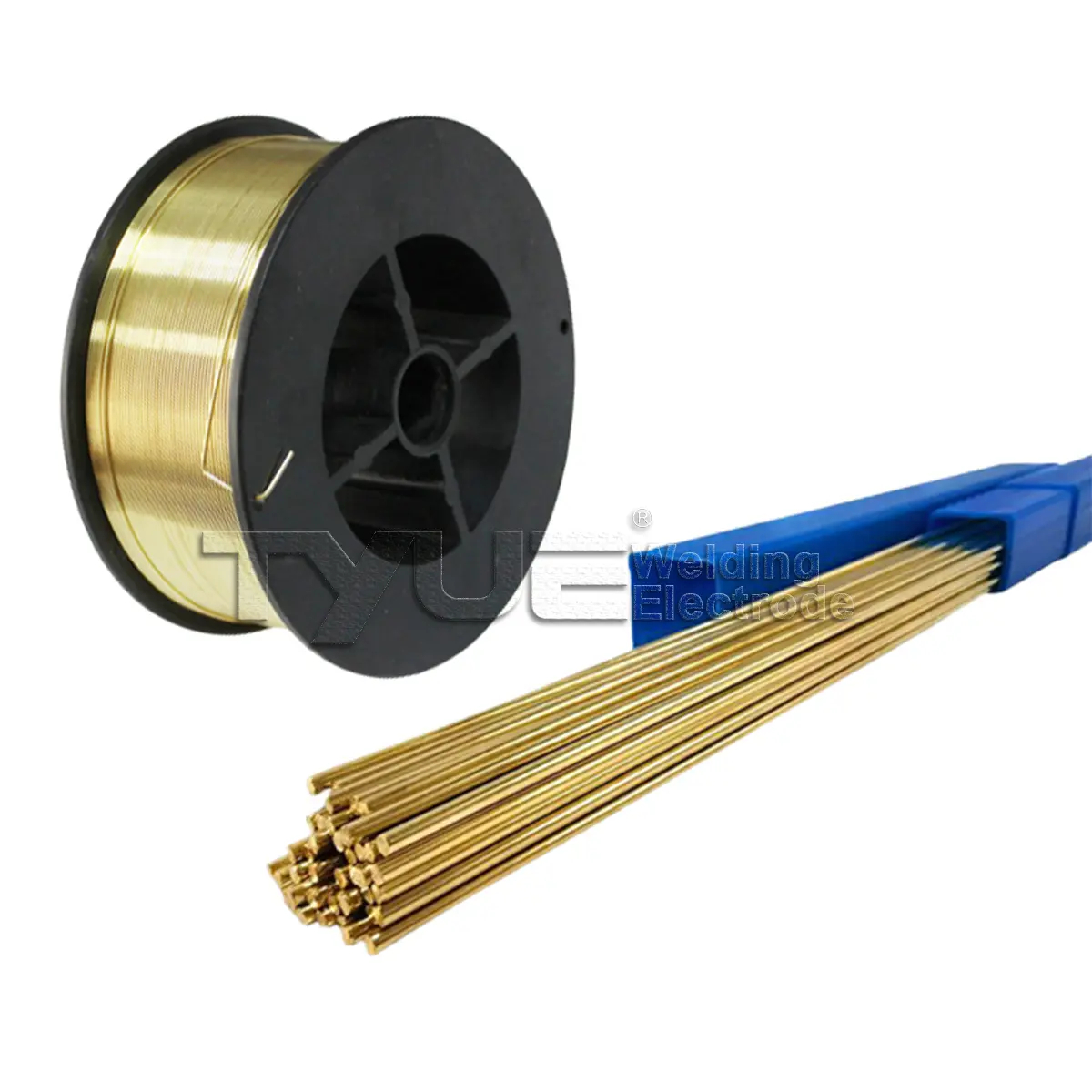

AWS A5.7 ERCuSn-C Copper Alloy Welding Wire’s optimized melting characteristics facilitate cleaner, faster welding with minimal oxidation. Post-weld cleanup is simplified by reducing slag formation, maintaining excellent wetting properties and ensuring uniform weld bead appearance. AWS A5.7 ERCuSn-C Copper Alloy Welding Wire excels in applications requiring an aesthetically pleasing finish without compromising structural strength. Consistent diameter and winding quality ensure uninterrupted wire feeding in automated systems, increasing productivity on large industrial projects.

AWS A5.7 ERCuSn-C Copper Alloy Welding Wire is welded with ERCuSn-C welding wire, which has excellent seawater corrosion resistance and is an indispensable material for offshore equipment and coastal infrastructure. The inherent thermal conductivity helps to effectively dissipate heat during welding and reduce the risk of warping of thin copper plates.

AWS A5.7 ERCuSn-C Copper Alloy Welding Wire is AWS A5.7 certified, guaranteeing compliance with global quality standards. AWS A5.7 ERCuSn-C Copper Alloy Welding Wire offers a balanced combination of workability, durability, and adaptability, making it the material of choice for professionals seeking reliable performance in copper alloy welding projects.

Post time: Apr-22-2025