Due to the phosphorus content, ERCuSn-A electrodes are particularly good at deoxidizing. This property is crucial when welding non-ferrous metals as it helps prevent oxidation during the welding process. By using ERCuSn-A electrodes, welders can achieve cleaner, stronger welds, minimizing the risk of defects that could compromise the integrity of the final product. This makes ERCuSn-A ideal for industries that require precision and reliability, such as the marine, automotive and construction industries.

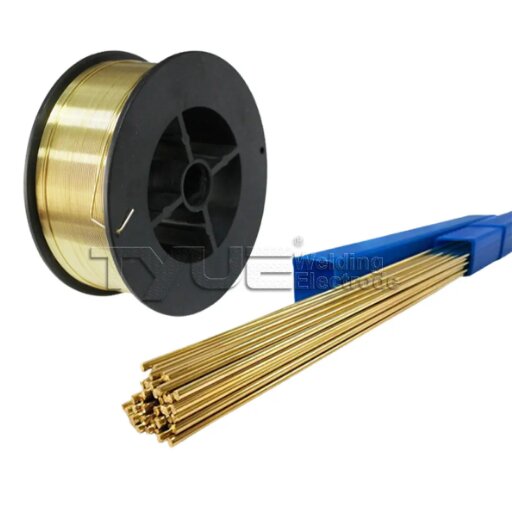

In addition to its excellent welding capabilities, the ERCuSn-A Tig Rod is also highly versatile. It can be used for both Tig and Mig welding processes, making it an essential addition to any welder’s toolkit. Whether you are working on an intricate design or a large project, the ERCuSn-A Tig Rod provides the flexibility needed to accommodate a variety of welding techniques. This versatility not only increases productivity, it also allows for a wider range of applications, from artistic metalwork to structural components.

ERCuSn-A electrodes are designed to be easy to use for welders of all skill levels. Their excellent flow characteristics and low spatter generation contribute to a smoother welding experience, allowing for greater control and precision. This ease of use is especially beneficial for welders who are new to welding or looking to improve their skills. By incorporating ERCuSn-A electrodes into their workflow, welders can achieve professional-grade results with confidence.

The ERCuSn-A (Phosphor Bronze A) Tig welding rod is an exceptional product that combines quality, versatility and ease of use. Its unique composition and deoxidizing properties make it ideal for welding bronze and brass, while its adaptability to both Tig and Mig processes ensures that it can meet the various needs of the welding industry. For those seeking to elevate their welding projects, the ERCuSn-A Tig welding rod is undoubtedly a wise investment that promises to deliver outstanding results time and time again. Embrace the superior quality of ERCuSn-A and experience the difference it can make in your welding work.

Post time: Nov-15-2024