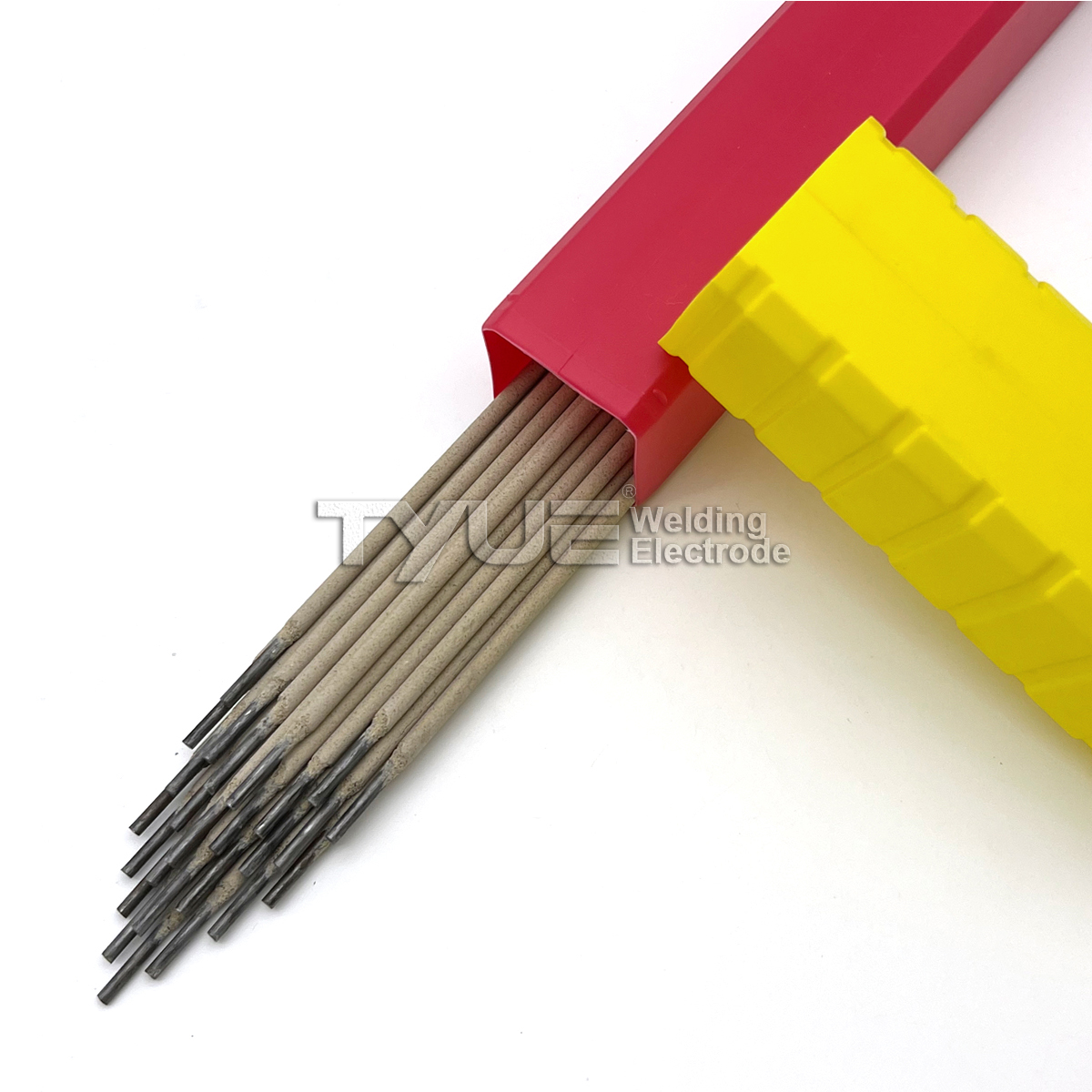

Carbon Steel Welding Electrode

J506

GB/T E5016

AWS A5.1 E7016

Description: J506 is a carbon steel electrode with low hydrogen potassium coating. AC and DC dual-purpose, can be welded in all positions. The performance stability of AC welding is inferior to that of DC welding. Deposited metal has good mechanical properties and crack resistance.

Application: Used for welding medium carbon steel and low alloy steel, such as Q345, 09Mn2Si, etc.

Chemical composition of weld metal(%):

|

C |

Mn |

Si |

S |

P |

|

≤0.12 |

≤1.60 |

≤0.75 |

≤0.030 |

≤0.035 |

Mechanical properties of weld metal:

|

Test item |

Tensile strength Mpa |

Yield strength Mpa |

Elongation % |

Impact value (J) |

|

|

-20℃ |

-30℃ |

||||

|

Guaranteed |

≥490 |

≥400 |

≥22 |

≥47 |

≥27 |

|

Tested |

520 ~ 580 |

≥410 |

25 ~ 33 |

60 ~ 230 |

55 ~ 205 |

Diffusion hydrogen content of deposited metal: ≤8.0mL/100g (glycerin method)

X-ray inspection: I grade

Recommended current:

|

Rod diameter (mm) |

2.0 |

2.5 |

3.2 |

4.0 |

5.0 |

5.8 |

|

Welding current (A) |

40 ~ 70 |

60 ~ 90 |

90 ~ 130 |

150 ~ 190 |

180 ~ 230 |

240 ~ 280 |

Wenzhou Tianyu Electronic Co., Ltd. was established in 2000. We have been engaged in the manufacturing of welding electrodes, welding rods, and welding consumables for more than 20 years.

Our main products include stainless steel welding electrodes, carbon steel welding electrodes, low alloy welding electrodes, surfacing welding electrodes, nickel & cobalt alloy welding electrodes, mild steel & low alloy welding wires, stainless steel welding wires, gas-shielded flux cored wires, aluminum welding wires, submerged arc welding. wires, nickel & cobalt alloy welding wires, brass welding wires, TIG & MIG welding wires, tungsten electrodes, carbon gouging electrodes, and other welding accessories & consumables.