|

Steel grade type |

Mould steel: |

|

Standard |

|

|

Production specifications |

Steel plate,Sheet, Coil,Flat bar,Round bar, Strip steel,wire,All kinds of forgings. |

|

Mchining |

Turning Milling Grinding Deep hole drilling: length max 9.8 meters. |

|

Range of work |

Round bar steel: 1mm to 2000mm Square-shape steel: 10mm to 1000mm steel Plate/sheet:0.08mm to 800mm Width: 10mm to 1500mm Lenth: We can supply any lenth based on the customer's requirement. Forging: Shafts with flanks/pipes/tubes/slugs/donuts/cubes/other shapes Tubings: OD: φ4-410 mm, with wall thickness ranging from 1-35 mm. |

|

Heat treatment |

Normalizing,Annealing,Tempering,Quenching,Hardening and tempering,Seasoning,Surface hardening,Carburizing |

AWS E10015-D2 CHEMICAL COMPOSITION AND MECHANICAL PROPERTIESL:

|

C ≤ |

Si ≤ |

Mn ≤ |

P ≤ |

S ≤ |

Cr |

Ni |

|

0.15 |

0.6 |

1.65-2.0 |

0.03 |

0.03 |

≤0.9 |

|

|

Mo |

Al |

Cu |

Nb |

Ti |

V |

Ce |

|

0.25-0.45 |

||||||

|

N |

Co |

Pb |

B |

Other |

MECHANICAL PROPERTIES:

|

Properties |

Conditions |

||

|

T (°C) |

Treatment |

||

|

Density (×1000 kg/m3) |

7.7-8.03 |

25 |

|

|

Poisson's Ratio |

0.27-0.30 |

25 |

|

|

Elastic Modulus (GPa) |

190-210 |

25 |

|

|

Tensile Strength (Mpa) |

1158 |

25 |

oil quenched, fine grained, tempered at 425°C |

|

Yield Strength (Mpa) |

1034 |

||

|

Elongation (%) |

15 |

||

|

Reduction in Area (%) |

53 |

||

|

Hardness (HB) |

335 |

25 |

oil quenched, fine grained, tempered at 425°C |

|

Properties |

Conditions |

||

|

T (°C) |

Treatment |

||

|

Thermal Conductivity (W/m-K) |

42.7 | 100 | |

|

Specific Heat (J/kg-K) |

477 | 50-100 | |

PHYSICAL PROPERTIES:

| Quantity | Value | Unit |

| Thermal expansion | 16 - 17 | e-6/K |

| Thermal conductivity | 16 - 16 | W/m.K |

| Specific heat | 500 - 500 | J/kg.K |

| Melting temperature | 1370 - 1400 | °C |

| Service temperature | 0 - 500 | °C |

| Density | 8000 - 8000 | kg/m3 |

| Resistivity | 0.7 - 0.7 | Ohm.mm2/m |

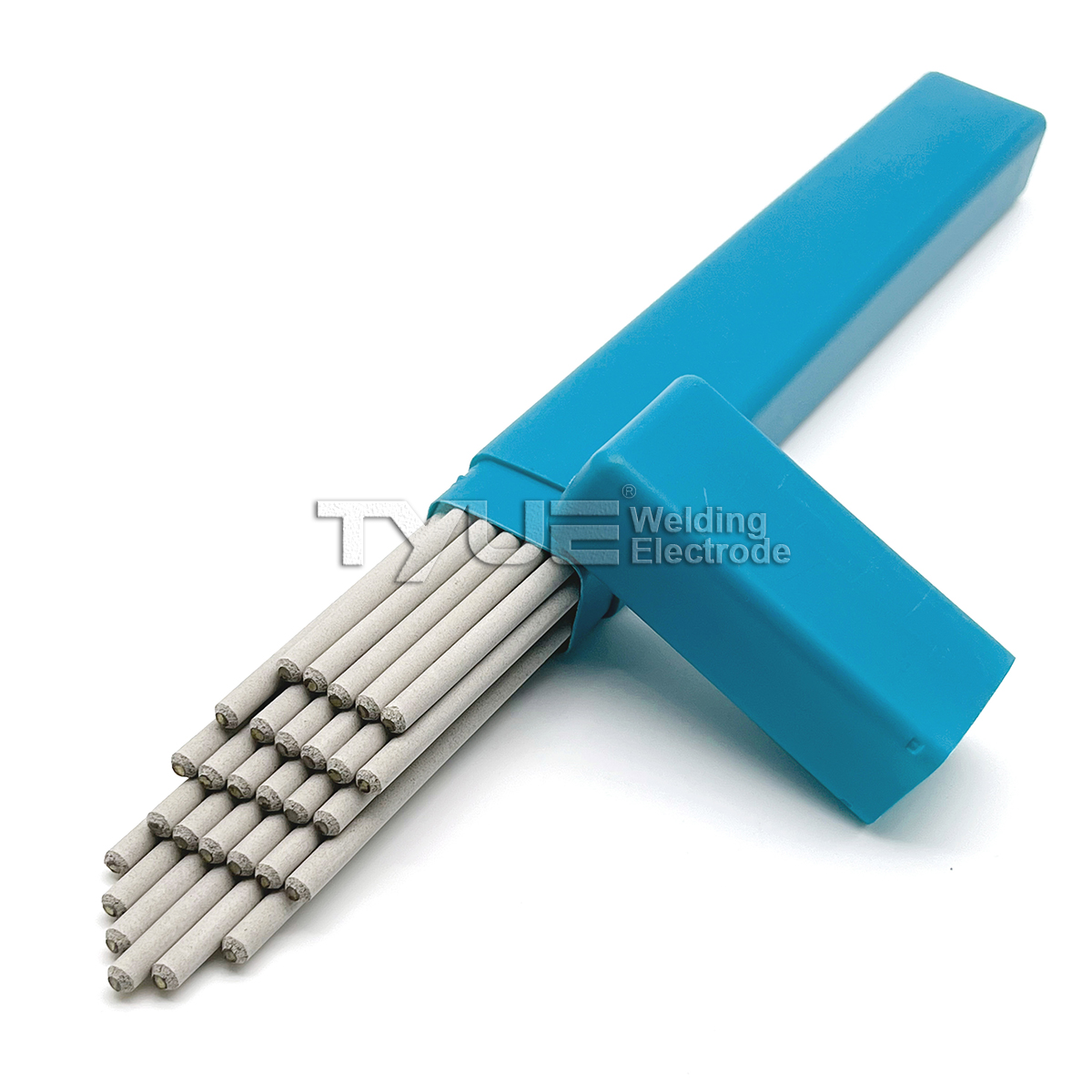

E7015-G Low Hydrogen Sodium Coating Welding Electrodes

DESCRIPTION:

It is a low temperature steel welding rod with low sodium hydrogen coating containing nickel. Full position welding can be carried out by dc reverse connection. In -80°C weld metal still has good impact toughness.

USES:

Welded -80°C working 1.5Ni steel structure.

DEPOSITED METAL CHEMICAL COMPOSITION:

| C | Mn | Si | Ni | S | P | |

| Standard | ≤0.08 | ≤1.25 | ≤0.60 | ≥1.00 | ≤0.035 | ≤0.035 |

| Test | 0.045 | 0.60 | 0.27 | 1.80 | 0.010 | 0.015 |

DEPOSITED METAL MECHANICAL PERFORMANCE:

| Tensile Strength Rm (MPa) | Yield Strength Rel (MPa) | Elongation A (%) | -80°C Impact Value Akv (J) | |

| Standard | ≥490 | ≥390 | ≥22 | ≥27 |

| Test | 530 | 445 | 30 | 100 |

REFERENTIAL CURRENT (DC+):

| Diameter (mm) | 3.2 | 4.0 | 5.0 | |

| Length (mm) | 350 | 400 | 400 | |

| Current (A) | 90-120 | 140-180 | 180-210 |

|

E12015-G |

According with GB E8515-G

Corresponding with AWS E12015-G |

Introduction: E12015-G is a kind of low-alloy high strength steel electrode with low-hydrogen natrium type coating. DCRP (Direct Current Reversed Polarity). All-position welding.

Applications: Used for welding low-alloy high strength steel structures with tensile strength of about 830MPa.

Chemical Composition of Deposited Metal (%)

|

Chemical Composition |

C |

Mn |

Si |

S |

P |

Mo |

|

Guarantee Value |

≤0.15 |

≥1.00 |

0.4~0.8 |

≤0.035 |

≤0.035 |

0.60~1.20 |

|

General Result |

≤0.10 |

~1.50 |

≤0.70 |

≤0.020 |

≤0.020 |

~0.90 |

Mechanical Properties of Deposited Metal

|

Test Item |

Rm(MPa) |

ReL or Rp0.2(Mpa) |

A(%) |

KV2(J) |

|

Guarantee Value |

≥830 |

≥740 |

≥12 |

—(normal temperature) |

|

General Result |

860~950 |

≥750 |

12~20 |

≥27 |

Diffusible Hydrogen Content in Deposited Metal: ≤5.0ml/100g(Chromatography)

X-ray Radiographic Inspection: ⅠDegree

INSTRUCTIONS:

1.The electrodes must be baked under 350-400℃ for an hour before welding, put into an insulation can and apply as soon as they are needed.

2.The stains on the weld like rust must be cleared away, and the weld must be preheated to about 200℃.

3.Weld can be tempered under 600-650℃ after welding so as to eliminate internal stress.