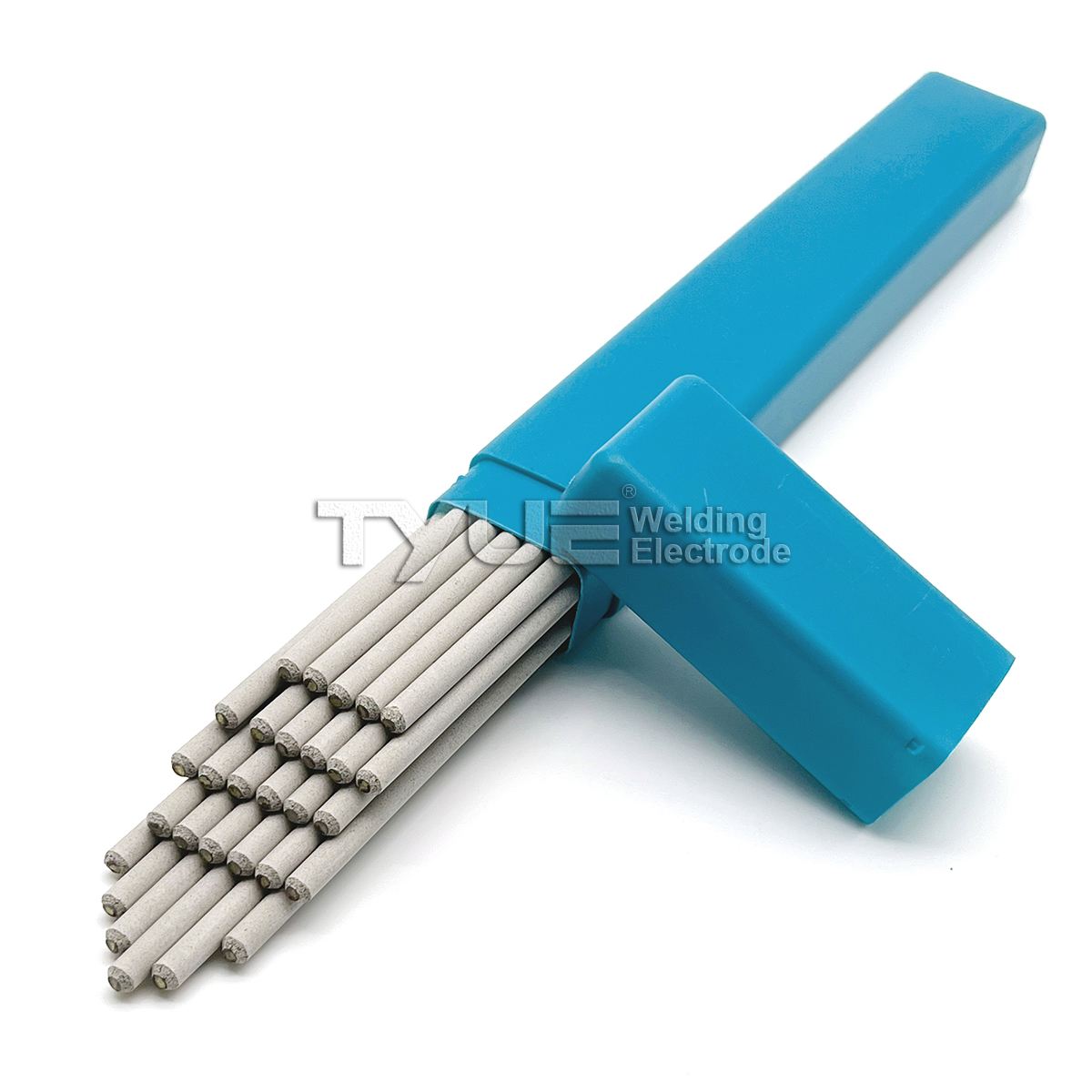

Low Alloy Steel Welding Electrode

J555G

GB/T E5510-G

AWS A5.5 E8010-G

Description: J555G is a high cellulose sodium-coated vertical down electrode. Use DCEP (direct current electrode positive). It is suitable for all-position vertical downward welding of the circular seam on the pipeline site. It can be welded on one side and formed on both sides, and the welding speed is fast.

Application: Used for girth welding of various low alloy steel pipes.

Chemical composition of weld metal(%):

|

C |

Mn |

Si |

S |

P |

|

≤0.20 |

≥1.00 |

≤0.50 |

≤0.035 |

≤0.035 |

熔敷金属力学性能 Mechanical properties of weld metal:

|

Test item |

Tensile strength Mpa |

Yield strength Mpa |

Elongation % |

Impact value (J) -30℃ |

|

Guaranteed |

≥540 |

≥440 |

≥17 |

≥27 |

X-ray inspection: II grade

Recommended current:

|

(mm) Rod diameter |

2.5 |

3.2 |

4.0 |

5.0 |

|

(A) Welding Current |

40 ~ 70 |

70 ~ 110 |

110 ~ 160 |

160 ~ 190 |

Notice:

1. Unpack the welding rod before use, and use it up as much as possible after unpacking;

2. Generally, there is no need to dry it again before welding, and it can be dried at 70~90°C for 1 hour when it is damp.

Wenzhou Tianyu Electronic Co., Ltd. was established in 2000. We have been engaged in the manufacturing of welding electrodes, welding rods, and welding consumables for more than 20 years.

Our main products include stainless steel welding electrodes, carbon steel welding electrodes, low alloy welding electrodes, surfacing welding electrodes, nickel & cobalt alloy welding electrodes, mild steel & low alloy welding wires, stainless steel welding wires, gas-shielded flux cored wires, aluminum welding wires, submerged arc welding. wires, nickel & cobalt alloy welding wires, brass welding wires, TIG & MIG welding wires, tungsten electrodes, carbon gouging electrodes, and other welding accessories & consumables.